Binder

Overview

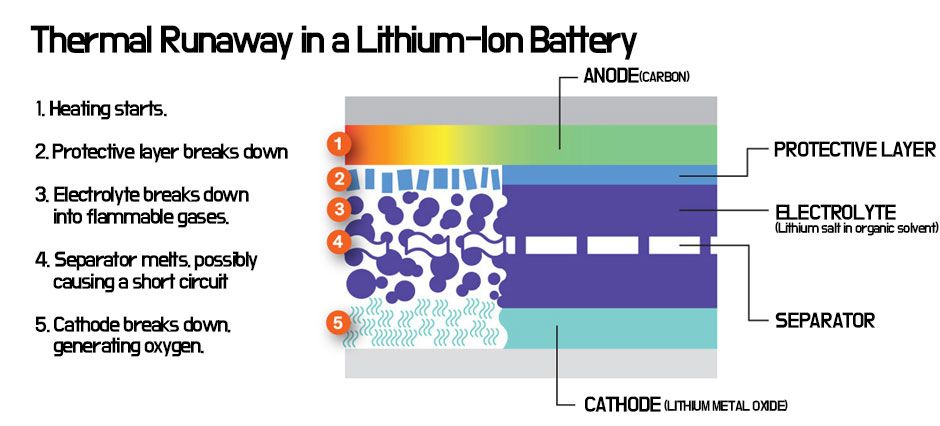

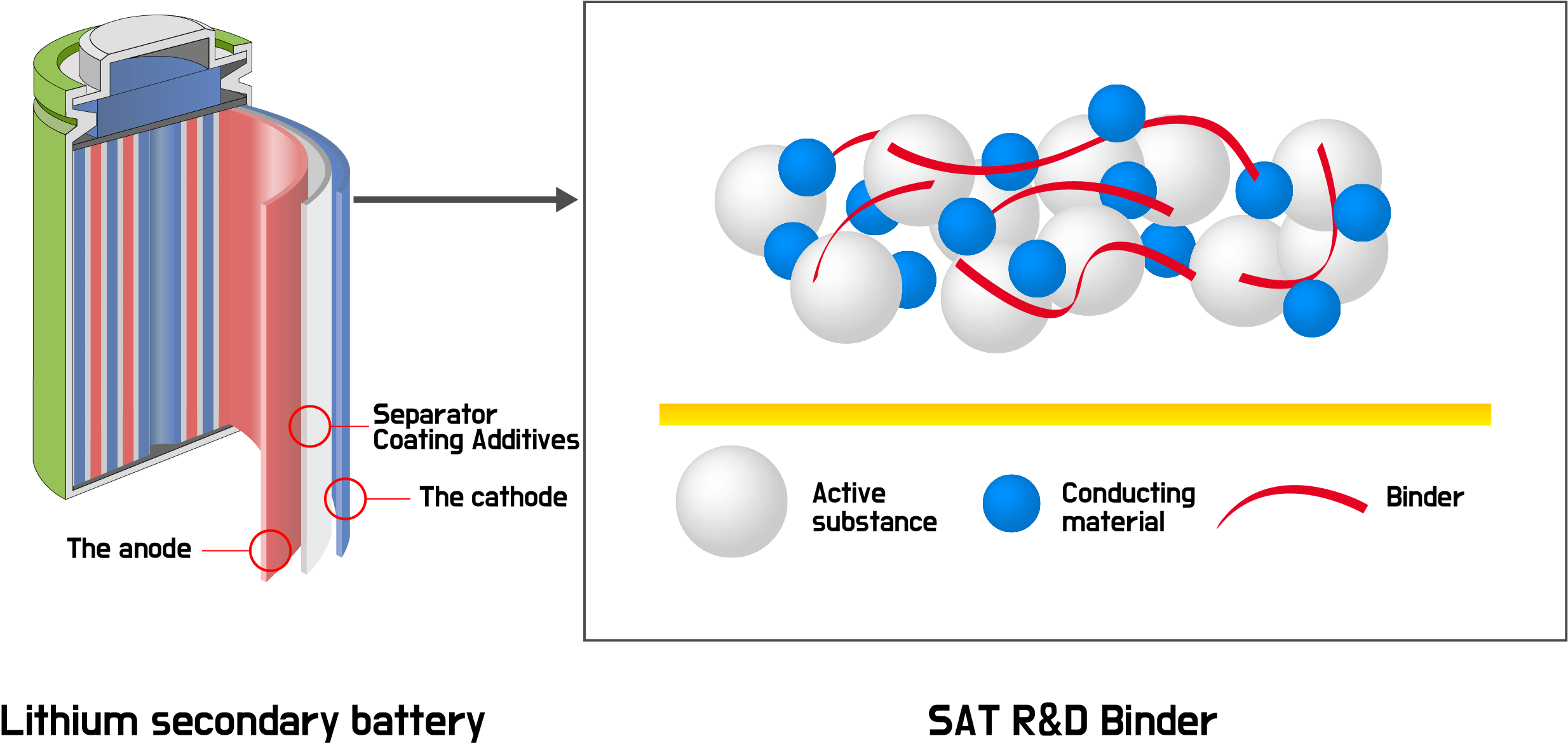

Lithium secondary cells consist largely of anode, cathode, electrolyte and separator, while anode and cathode consist of active materials , conducting materials and binders.

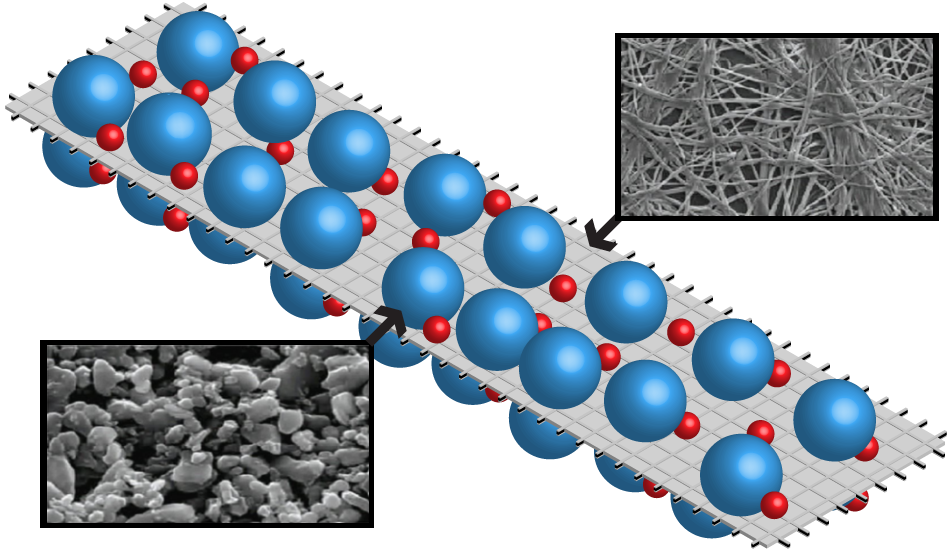

The binder that the SAT developed is a material that binds the active material and the conducting material to the current collecting layer in the electrodes of the secondary battery. The material with adhesive strength contributes to electrochemical stability and overall battery quality improvement even if small amount of it is used when applied to the battery.

Applied Area

The binder material binds the active material and the conducting material to the current collecting layer in the electrodes of the secondary battery.

Low usage of binder with strong adhesion can contribute to electrochemical stability and overall battery quality, directly or indirectly affecting the lifespan of the electric vehicle or ESS batteries.